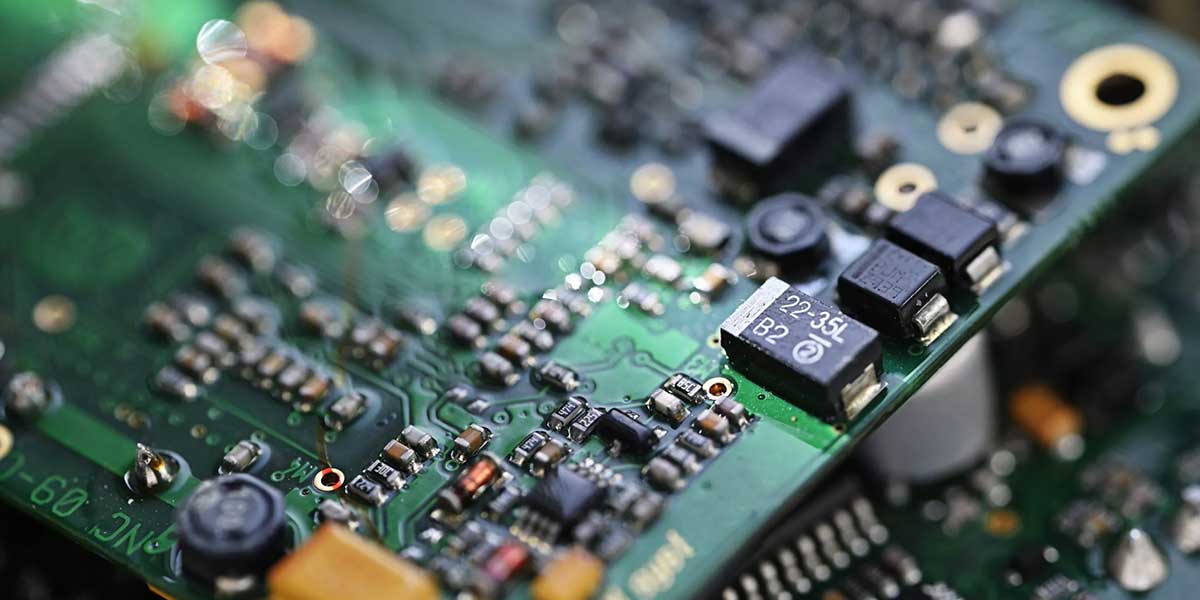

The history of PCB assembly (Printed Circuit Board assembly) is closely tied to the development of electronic technology and the need for efficient and reliable methods of interconnecting electronic components. Here’s a comprehensive overview of the history of PCB assembly:

1. Early Developments

- In the early 20th century, electronic circuits were primarily constructed using point-to-point wiring methods. Components were individually wired together, which was time-consuming and prone to errors.

- In the 1940s, during World War II, the demand for more efficient and reliable electronic systems led to the development of the first printed circuit boards. These early PCBs used rudimentary techniques, such as metal stencils and adhesive tape, to create conductive pathways on insulating boards.

2. Advent of the “Auto-Assembly”

- In the 1950s, advancements in industrial automation and electronics allowed for the development of automated assembly processes.

- The “Auto-Assembly,” introduced by the United States Army Signal Corps, was an early attempt at automating PCB assembly. It involved the use of punched paper tapes to guide the assembly machines and the use of discrete components.

- The Auto-Assembly reduced the manual labor required for PCB assembly, improving efficiency and consistency.

3. Introduction of Through-Hole Technology (THT)

- In the 1960s, the introduction of Through-Hole Technology (THT) revolutionized PCB assembly.

- THT involved drilling holes in the PCB and inserting component leads through the holes. The leads were then soldered on the opposite side of the board to create electrical connections.

- THT allowed for faster assembly and facilitated the use of a wider range of electronic components, including resistors, capacitors, and integrated circuits (ICs).

4. Surface Mount Technology (SMT) Era

- In the 1980s, Surface Mount Technology (SMT) emerged as a more advanced and compact method of PCB assembly.

- SMT eliminated the need for drilled holes by directly mounting components on the surface of the PCB.

- SMT components, including smaller ICs, resistors, capacitors, and other passive devices, were designed with smaller footprints and solderable leads or pads.

- SMT offered several advantages over THT, including higher component density, improved electrical performance, and faster assembly times.

5. Miniaturization and Advanced Assembly Techniques

- In the late 20th century and early 21st century, PCB assembly continued to evolve with the demand for smaller and more complex electronic devices.

- Miniaturization became a key focus, leading to the development of finer pitch components, advanced packaging techniques (such as Ball Grid Array – BGA), and multi-layer PCBs.

- Advanced assembly techniques, such as automated pick-and-place machines, reflow soldering, and solder paste printing, further improved the efficiency and precision of PCB assembly.

6. Integration of Advanced Technologies

- In recent years, PCB assembly has integrated advanced technologies such as robotics, machine learning, and automated optical inspection (AOI) systems.

- Robotics and automation have further enhanced the speed and accuracy of component placement, soldering, and inspection processes.

- Machine learning algorithms and AI-based systems are being employed for process optimization, defect detection, and quality control in PCB assembly.

- AOI systems utilize cameras and image recognition algorithms to inspect PCBs for defects, ensuring higher quality and reliability.

The history of PCB assembly reflects the continuous advancements in electronics and manufacturing technologies. From manual wiring to automated assembly, from through-hole to surface mount technology, and from simple circuits to highly integrated components, PCB assembly has played a crucial role in enabling the development of modern electronic devices.