Industrial Control: Understanding the Role of Electronic Boards in Automation

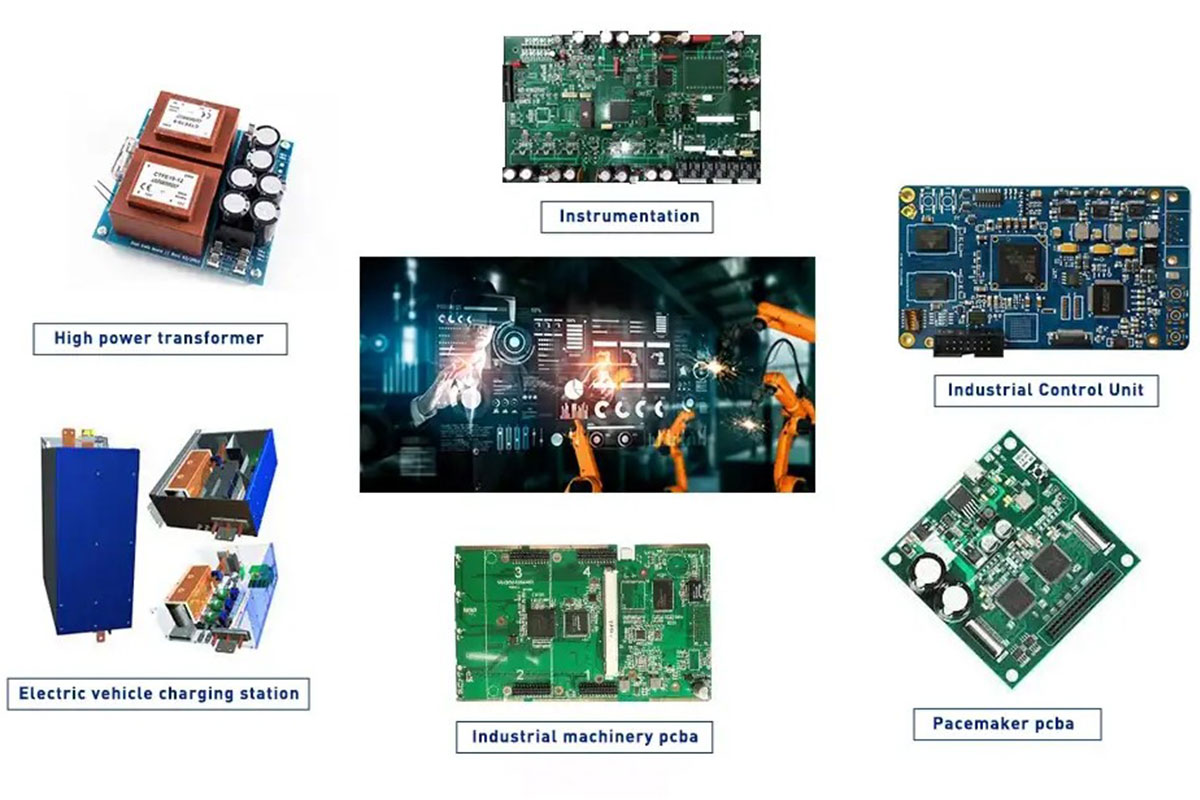

Industrial control is the use of technology to monitor and control industrial processes. It involves the use of electronic boards or printed circuit boards (PCBs) to provide control signals to various devices in the system. As a manufacturer and assembler of electronic boards, HIGHPCB is well-positioned to provide customers with the necessary hardware to implement industrial control systems. In this article, we will discuss the role of electronic boards in industrial control and highlight the capabilities of HIGHPCB in this area.

Role of Electronic Boards in Industrial Control

Electronic boards are vital components of industrial control systems. They provide a means of connecting various devices in the system and sending control signals to them. For example, in a manufacturing plant, electronic boards can be used to control the speed of a conveyor belt, the temperature of an oven, or the pressure of a hydraulic system. In an oil refinery, electronic boards can be used to monitor and control the flow of oil and gas through the pipelines. In short, electronic boards provide the necessary intelligence to industrial control systems, enabling them to operate efficiently and reliably.

Capabilities of HIGHPCB in Industrial Control

HIGHPCB has extensive experience in the design, manufacture, and assembly of electronic boards for industrial control systems. The company has a team of skilled engineers who can work closely with customers to develop customized solutions that meet their specific requirements. Some of the key capabilities of HIGHPCB in industrial control include:

- Design Expertise: HIGHPCB has a team of experienced designers who can create electronic board layouts that are optimized for industrial control applications. The company uses the latest design tools and techniques to ensure that the boards are reliable, efficient, and cost-effective.

- Manufacturing Excellence: HIGHPCB has a state-of-the-art manufacturing facility that is equipped with the latest equipment and technology. The company uses advanced processes to ensure that the boards are manufactured to the highest standards of quality and reliability.

- Assembly and Testing: HIGHPCB has a team of skilled technicians who can assemble and test electronic boards to ensure that they meet the customer’s specifications. The company uses the latest testing equipment and techniques to ensure that the boards are fully functional and reliable.

Conclusion

Industrial control is a critical field that requires the use of high-quality electronic boards. As a manufacturer and assembler of electronic boards, HIGHPCB is well-positioned to provide customers with the necessary hardware to implement industrial control systems. The company has extensive experience in the design, manufacture, and assembly of electronic boards for industrial control applications. Its team of skilled engineers and technicians can work closely with customers to develop customized solutions that meet their specific requirements. If you are looking for a reliable partner for your industrial control needs, HIGHPCB is the right choice.