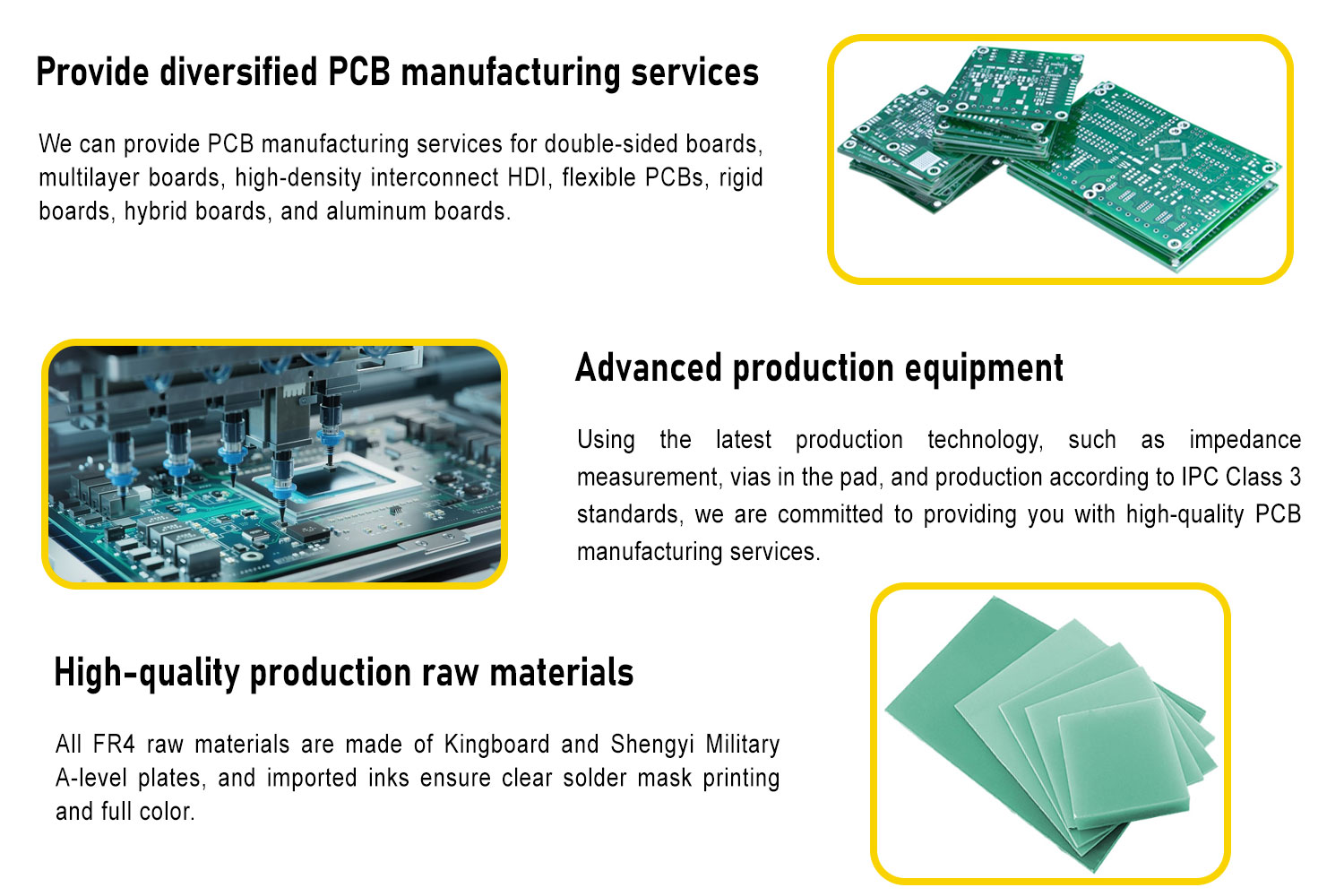

One of our unique and high-quality services is printing with excellent quality and high accuracy, PCB multilayer, which distinguishes us in this industry.

PCB Fabrication:

- Production of PCB with materials; Fiber (FR4), half fiber (CEM), bone (XPC), and aluminum.

- Production of all types of PCB; Single-layer, double-layer metalized, and multilayer.

- Variety in the final cover includes; Anti-oxide copper, hot air, and gold plating.

- The variety of solder colors includes; Green, blue, red, white, black, and…

- Types of final cut; CNC, V-cut, and Punch.

Product categories in PCB fabrication:

HIGHPCB has 18 types of PCB manufacturing products;

- multilayer PCB; 1-40layer

- HDI PCB; 4-24layers

- PCB prototype; 1-32layers

- High-frequency PCB; 1-40layers

- Hybrid PCB; 1-40layers

- Rogers PCB; 1-40layers

- Rigid-flex PCBs; 1-12layers

- Metal core PCB; 1-40layers

- LED PCB; 1-6layers

- Gold finger PCB; 1-32layers

- RF printed circuit boards; 1-32layers

- Ceramic PCB;

- FR4 PCB; 1-32layers

- RoHS circuit boards;

- High TG PCB; 1-32layers

- Aluminum PCB; 1-6layers

- Thick copper PCB; 1-16layers

- Impedance PCB; 1-4layers

One feature that distinguishes HIGHPCB from other colleagues active in the field of PCB printing is the effort of the HIGHPCB team to implement the rules of Design For Manufacturing – DFM in its customers’ design. After receiving the design file from the customers, After receiving the design file from the customers, the engineering team of HIGHPCB reviews the file. It matches it with the IPC standards, and if there is any non-compliance with these standards or design problems, it gives customers free advice regarding these problems.

The factors that affect the price of PCB are:

- Cut type

- Number and diameter of vias

- number of PCBs (sampling or circulation)

- Printed circuit board fiber material

- Number of layers

- Board dimensions

- Solder mask

- Silk Screen

- Minimum di-electrical

- Minimum track thickness

Finally, this diversity in PCB manufacturing technology assures you that you can leave the PCB manufacturing process to us quickly and confidently.

Types of printed circuit fibers:

PCBs have copper tracks to connect the various components’ holes. They are specifically designed for each circuit and are very easy to build. However, PCB fabrication requires special tools. Types of printed circuit fibers mainly include the following:

- Single-sided PCBs

- double-sided PCBs

- Multilayer PCBs

- Rigid PCBs

- Flex PCBs

- Rigid-flex PCB

Double-Sided PCBs

This type of PCB is much more widely used than single-sided boards. Both sides of the fiber substrate contain metallic conductive layers, and elements are connected. PCB holes called vias allow circuits on one side to connect to circuits on the other.

Multilayer PCB

These PCBs increase the density and complexity of PCB designs by adding additional layers beyond the top and bottom layers seen in a double-sided configuration. With the ability to access multiple layers in multilayer printed circuit board configurations, multilayer PCBs allow designers to create very thick and highly complex designs.

The additional layers used in this design are the power plates that provide the circuit’s power supply and reduce the levels of electromagnetic interference emitted by designs. Lower EMI levels are achieved by placing the signal levels in the middle of the power planes.

Rigid-PCB

In addition to having different layers and sides, printed circuit fibers can also have invariability; Invariability means that the printed circuit fiber is not flexible. Most customers usually think of non-flexible PCBs when they picture a PCB. Rigid printed circuit boards use a solid substrate material such as fiberglass. The motherboard inside a computer is the best example of a non-flexible PCB.

Flexible PCB

In general, it is a flexible plastic. This primary material allows the board to be bent into shapes that rigid boards cannot rotate or move during use without damaging the circuits on the printed circuit board. Although flex boards tend to charge more than rigid PCBs, they have many advantages. For example, they can handle heavy or bulky wiring in high-end equipment such as satellites and Restore, where weight and space matter. Flex boards can also be supplied in single-sided, double-sided, or multi-layered formats.

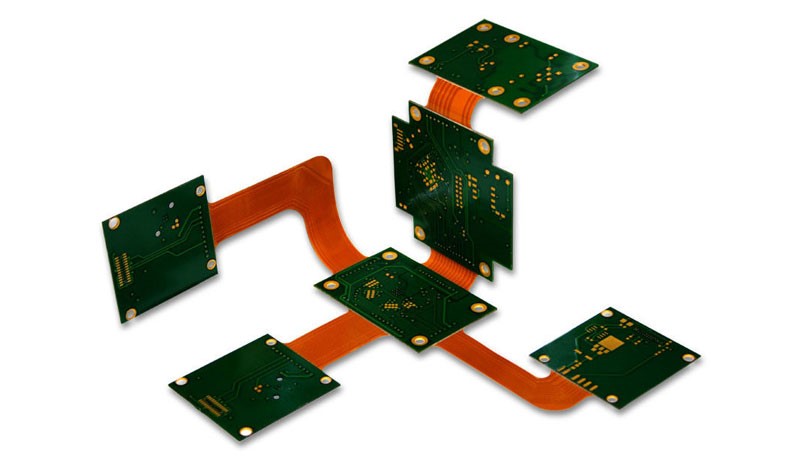

Rigid-flex PCB

These boards are a combination of Rigid and Flex boards, considered one of the most widely used types of printed circuit fiber in the electronics industry for more complex tasks. A flexible PCB is more straightforward to assemble than a rigid PCB connected to a flex circuit board. If the design is requested, these boards can have more combinations, And all the advantages of Rigid and Flex boards can be used in the type of fibers.