Devices Powered by PCBs and IoT Revolutionizing the World

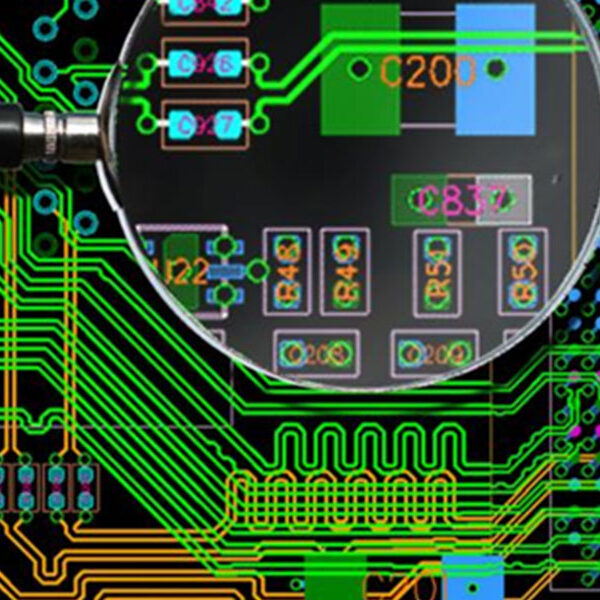

In recent years, the convergence of printed circuit boards (PCBs) and the Internet of Things (IoT) has unleashed a wave of innovation, transforming the way we interact with devices and the world around us. The marriage of PCB technology and IoT connectivity has given rise to a new generation of smart devices that are revolutionizing…