In PCB manufacturing, precision is everything — and it begins long before the first board is fabricated. At the heart of every successful PCB project lies a well-prepared and well-managed Bill of Materials (BOM). A carefully structured BOM not only ensures a smooth transition from design to production but also reduces costs, prevents delays, and enhances long-term product reliability.

In this comprehensive guide, we’ll explain what a BOM is, why it matters, and how to manage it effectively to get the best results in your PCB production — especially when working with a trusted partner like HighPCB.

What Is a BOM in PCB Projects?

A Bill of Materials (BOM) is a detailed list of all the components, materials, and assemblies required to build a printed circuit board (PCB). It’s an essential document that bridges the gap between the design and manufacturing phases.

For PCB projects, the BOM acts as a roadmap — defining every resistor, capacitor, IC, connector, and even mechanical components like heatsinks or spacers. Without a clean, complete BOM, even the most advanced design files are practically useless.

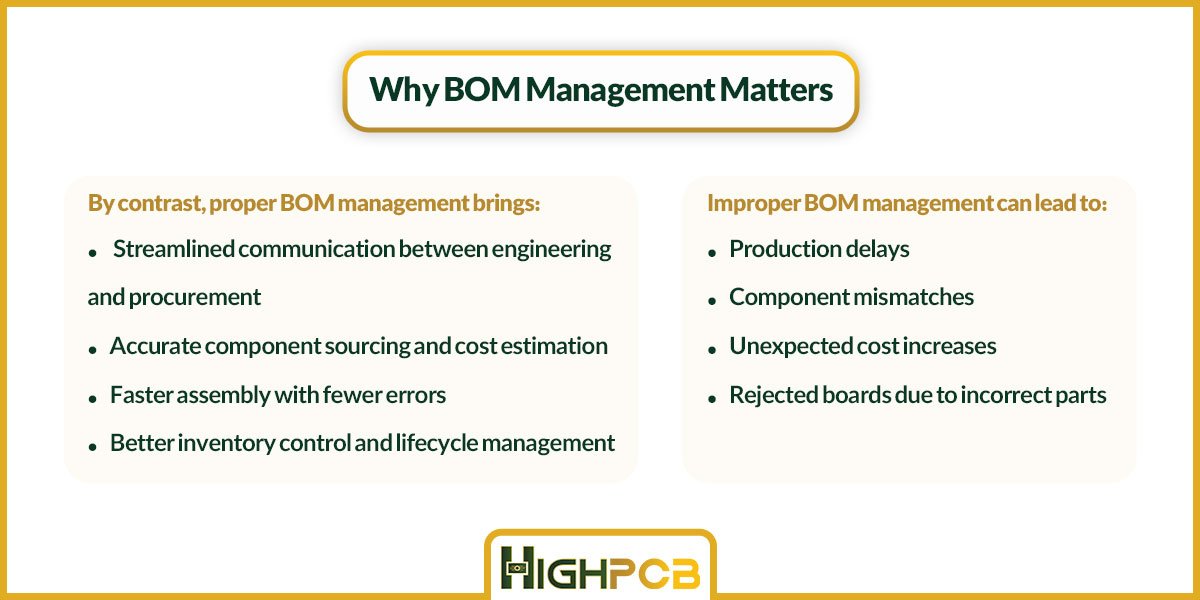

Why BOM Management Matters

Improper BOM management can lead to:

- Production delays

- Component mismatches

- Unexpected cost increases

- Rejected boards due to incorrect parts

By contrast, proper BOM management brings:

- ✅ Streamlined communication between engineering and procurement

- ✅ Accurate component sourcing and cost estimation

- ✅ Faster assembly with fewer errors

- ✅ Better inventory control and lifecycle management

In high-mix, low-volume (HMLV) environments like prototyping or rapid development cycles, these benefits become mission-critical.

Typical Components of a PCB BOM

A complete BOM for a PCB should include the following columns:

| Field | Description |

| Item Number | Reference number for each line |

| Quantity | Number of units per board |

| Reference Designator(s) | Component positions on the PCB (e.g., R1, C5, U3) |

| Part Description | Details like value, tolerance, size (e.g., 10kΩ ±1%, 0805) |

| Manufacturer Name | Name of the component manufacturer |

| Manufacturer Part Number (MPN) | Unique identifier for sourcing |

| Footprint/Package | Mechanical size, like 0805, SOIC-8 |

| Alternative Parts | (Optional) Approved alternates for sourcing flexibility |

| Notes | Assembly instructions or specifications |

The more accurate your BOM is, the smoother the sourcing and assembly processes will be.

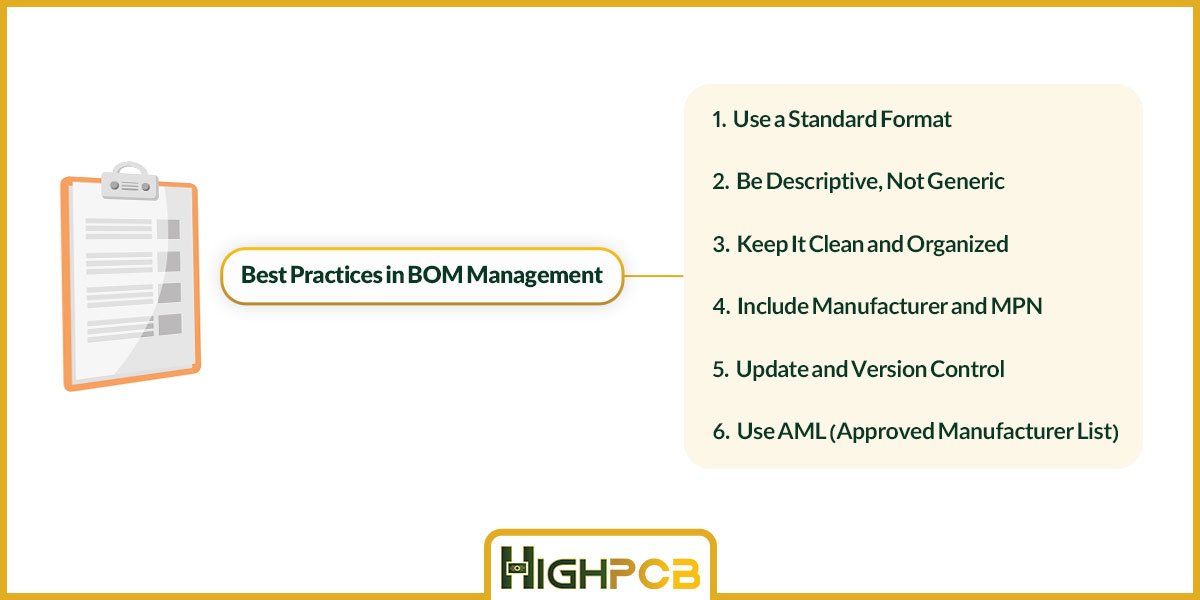

Best Practices in BOM Management

Use a Standard Format

Stick to universally accepted formats like Excel, CSV, or XML. Avoid PDFs or Word docs — they are harder to process.

Be Descriptive, Not Generic

Don’t just write “10k resistor.” Specify tolerance, footprint, and power rating: e.g., “Resistor, 10kΩ ±1%, 0.1W, 0805.”

Keep It Clean and Organized

Avoid merged cells, blank rows, or inconsistent headers. Keep designators in order (e.g., C1, C2, C3…).

Include Manufacturer and MPN

Use verified part numbers from trusted suppliers or distributors. This eliminates ambiguity.

Update and Version Control

Every BOM should have a version number and date. This helps in tracking changes during iterations.

Use AML (Approved Manufacturer List)

List preferred manufacturers to ensure consistency and avoid unqualified alternates.

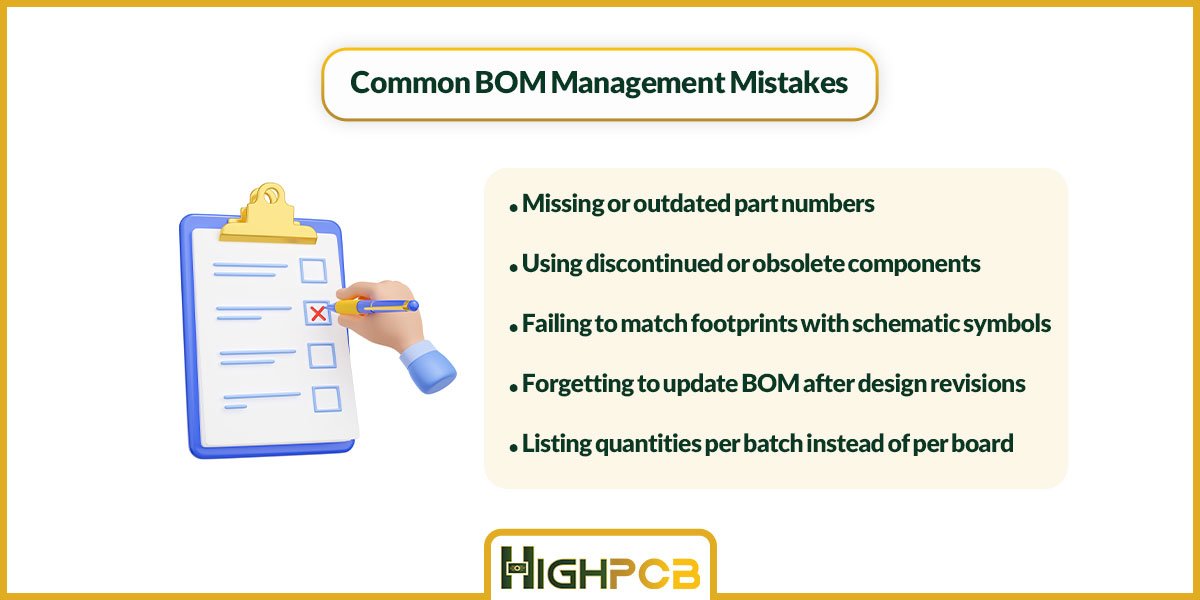

Common BOM Management Mistakes

- ❌ Missing or outdated part numbers

- ❌ Using discontinued or obsolete components

- ❌ Failing to match footprints with schematic symbols

- ❌ Forgetting to update BOM after design revisions

- ❌ Listing quantities per batch instead of per board

Avoiding these issues is key to a successful handoff from engineering to purchasing and assembly.

How to Streamline Your BOM Process

Use CAD-Integrated BOM Tools

Many PCB design tools like Altium Designer, KiCad, or Eagle allow BOM exports directly from the schematic. This ensures alignment between design intent and documentation.

Connect Your BOM to ERP or Inventory Systems

Syncing your BOM with ERP software improves part availability checks and real-time cost estimates.

BOM Scrubbing

Before sending your BOM to a manufacturer like HighPCB, conduct a BOM scrub. This means checking for:

- Obsolete components

- Conflicting descriptions

- Incomplete or duplicated entries

A clean BOM saves you time, money, and production headaches.

BOM’s Role in PCB Assembly

In PCB assembly, the BOM works alongside:

- Pick and Place Files

- Gerber Files

- Assembly Drawings

It is used for:

- Selecting reels of components for SMT machines

- Programming feeders based on reference designators

- Inspecting final boards for accuracy

An inaccurate BOM can lead to misplaced parts, faulty connections, and even batch-wide rejections. That’s why manufacturers like HighPCB place such importance on BOM validation before production begins.

How HighPCB Helps You Optimize BOM Management

At HighPCB, we don’t just receive your BOM — we analyze, validate, and optimize it for manufacturing success. Here’s how we support you:

- 🔍 BOM Review Services: Our engineers check for mismatches, missing data, and obsolete components.

- 📦 Substitution Suggestions: When a part is unavailable, we suggest functionally equivalent alternatives.

- 💰 Cost Optimization: We identify components that can lower your BOM cost without sacrificing quality.

- 🔄 Version Control: We manage BOM iterations carefully, ensuring you always build from the correct file.

- 🛠 DFM Feedback: We alert you to any assembly or layout challenges tied to your BOM selections.

This proactive approach minimizes production risks and ensures your project moves forward efficiently.

Conclusion: BOM Is More Than a List — It’s a Strategy

A well-structured BOM is not just a spreadsheet — it’s a strategic tool that can make or break your PCB project. Proper BOM management ensures accurate sourcing, faster turnaround, fewer errors, and better cost control.

At HighPCB, we partner with engineers, startups, and global OEMs to bring their designs to life — starting with a bulletproof BOM.

👉 Ready to Submit Your BOM?

Let our team at HighPCB help you review and optimize your Bill of Materials for a smoother, smarter production process. Contact us for more information.