Choosing the right type of printed circuit board (PCB) is a critical decision in any electronic product development process. Whether you’re building a wearable medical device, a rugged industrial controller, or a foldable consumer gadget, the choice between Flex PCBs and Rigid PCBs can make or break your design.

In this comprehensive guide, we’ll help you understand the key differences, benefits, and use cases of both PCB types — so you can decide which one fits your project best. Plus, we’ll show you how HighPCB supports both technologies with precision and flexibility.

HighPCB is one of the biggest pcb manufacturing factories in China. Click on the link for more information.

Introduction: Why PCB Type Matters

Every product starts with a vision — but the performance, cost, and manufacturability of that product heavily depend on choosing the right type of PCB. Flex and rigid PCBs each have distinct properties, and selecting the wrong type can result in unnecessary costs, mechanical failures, or wasted development time.

Understanding their differences is essential not just for engineers, but also for product managers and procurement teams aiming for efficient, scalable manufacturing.

What Is a Rigid PCB?

A Rigid PCB is the traditional circuit board made from inflexible materials such as fiberglass-reinforced epoxy resin (typically FR4). These boards maintain a fixed shape and do not bend.

🔧 Key Features:

- Excellent mechanical strength

- Cost-effective for high-volume production

- Easy to design and assemble

- Compatible with standard components and processes

📦 Common Applications:

- Desktop computers, servers

- Consumer electronics like TVs and printers

- Industrial equipment

- Automotive control units

Rigid PCBs are ideal when space isn’t constrained, and the design doesn’t require movement or bending.

What Is a Flex PCB?

A Flexible PCB (Flex Circuit) is made from materials like polyimide, which allows the board to bend, twist, and conform to unique shapes. Flex PCBs can withstand dynamic motion and are often lighter and thinner than their rigid counterparts.

🔧 Key Features:

- Excellent bendability

- Lightweight and space-saving

- High vibration and shock resistance

- Can fit into 3D structures

📦 Common Applications:

- Wearable electronics

- Foldable phones and tablets

- Medical implants and diagnostics devices

- Aerospace systems and satellites

Flex PCBs open up design possibilities where rigid boards simply won’t fit.

Flex vs. Rigid PCB: Comparison Table

| Feature | Rigid PCB | Flexible PCB |

| Flexibility | None | High (can bend and twist) |

| Weight | Heavier | Lightweight |

| Durability | Strong in static environments | Excellent in dynamic environments |

| Design Freedom | Limited to 2D planes | Allows 3D folding and layering |

| Cost | Lower (especially in volume) | Higher due to materials and complexity |

| Assembly | Easier, standardized processes | Requires special handling and fixturing |

| Vibration Resistance | Moderate | Superior |

| Thermal Dissipation | Standard | Better due to thin substrate |

| Typical Applications | General electronics, automotive | Wearables, aerospace, medical, foldables |

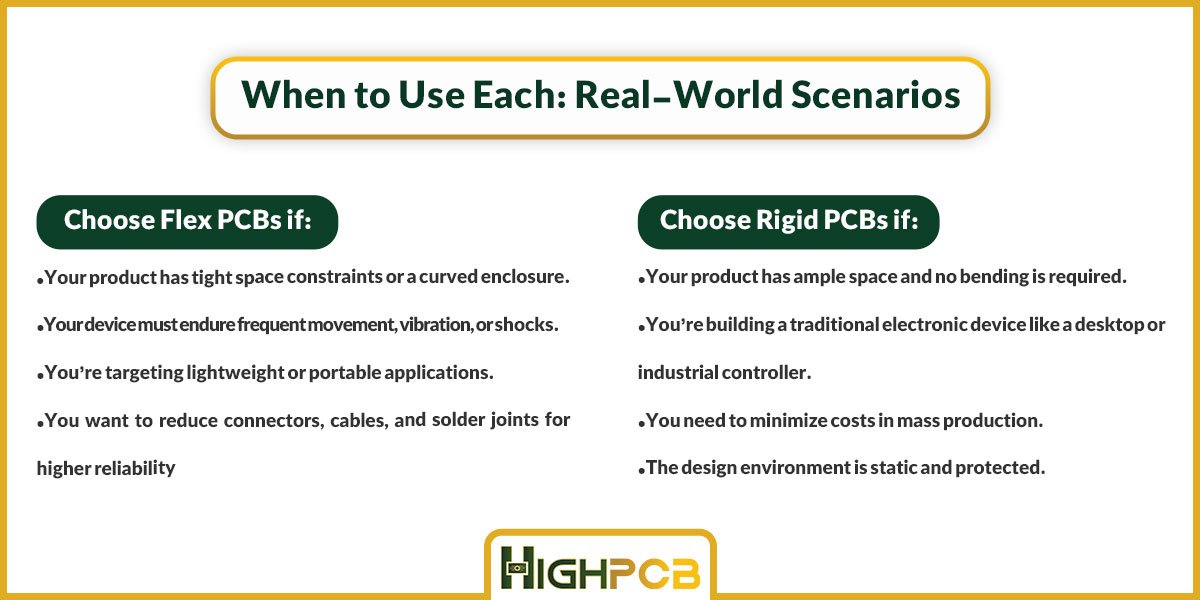

When to Use Each: Real-World Scenarios

✅ Choose Rigid PCBs if:

- Your product has ample space and no bending is required.

- You’re building a traditional electronic device like a desktop or industrial controller.

- You need to minimize costs in mass production.

- The design environment is static and protected.

✅ Choose Flex PCBs if:

- Your product has tight space constraints or a curved enclosure.

- Your device must endure frequent movement, vibration, or shocks.

- You’re targeting lightweight or portable applications.

- You want to reduce connectors, cables, and solder joints for higher reliability.

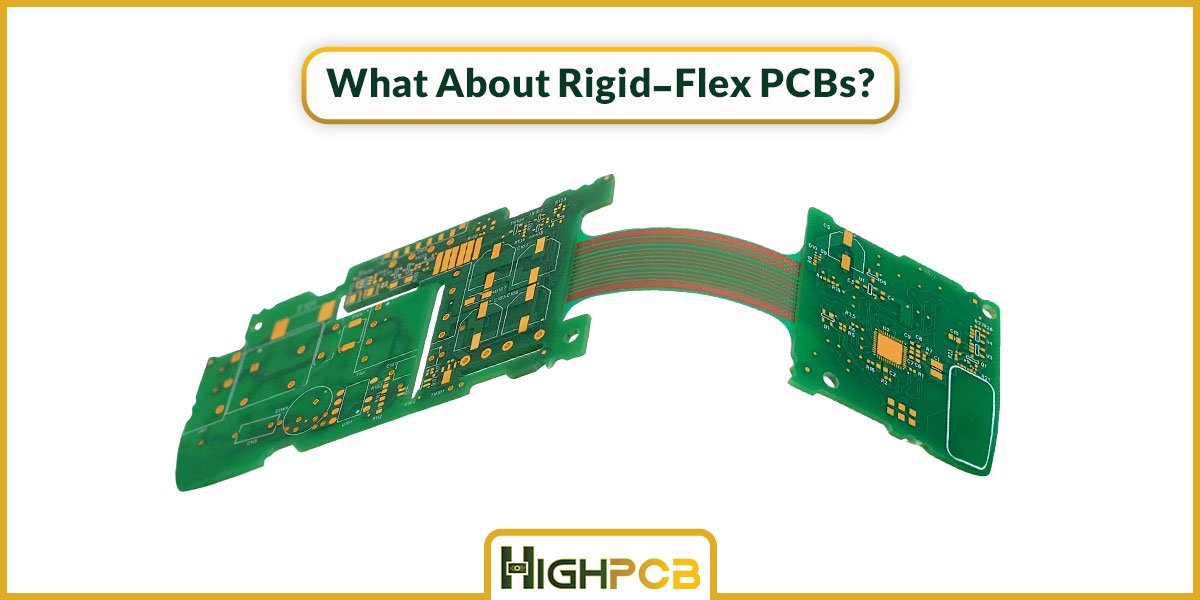

What About Rigid-Flex PCBs?

Sometimes, your design requires the best of both worlds.

Rigid-Flex PCBs combine rigid sections (for mounting components) with flexible interconnects. These are particularly useful in:

- Military and aerospace applications

- Foldable and clamshell devices

- High-end cameras and compact gadgets

Though more complex and costly, Rigid-Flex PCBs reduce interconnect failures, save space, and boost mechanical reliability.

Design & Manufacturing Considerations

🛠 Rigid PCBs:

- Easier to design, simulate, and fabricate.

- Standard FR4 materials and multilayer stackups.

- Widely supported by EMS (electronics manufacturing services) providers.

🛠 Flex PCBs:

- Require attention to bend radius, material thickness, and trace routing.

- Use of rolled annealed copper is recommended for better flexibility.

- Special adhesives and coverlays must be applied instead of solder mask.

- Assembly must avoid placing components in flex zones.

Designing Flex PCBs without considering these aspects can lead to mechanical failure or poor yield.

How HighPCB Supports Both Rigid and Flex Designs

At HighPCB, we understand the unique needs of each design — and offer full support for both rigid and flexible technologies. Here’s what sets us apart:

- ✅ Expert DFM analysis for both rigid and flex circuits

- ✅ Rapid prototyping with flexible MOQ (Minimum Order Quantity)

- ✅ Material selection guidance (FR4, polyimide, PI+PET blends)

- ✅ Support for multilayer, Rigid-Flex, and HDI PCBs

- ✅ BOM review to avoid obsolete or incompatible components

Our engineers work closely with your design team to ensure manufacturability, reduce rework, and maintain high product quality — from prototype to mass production.

Conclusion: Which PCB Type Is Right for You?

The choice between Rigid and Flex PCBs depends on your design goals, budget, space constraints, and mechanical requirements. In many cases, rigid PCBs are sufficient. But in others, especially with compact or dynamic devices, flexible PCBs are not just better — they’re essential.

At HighPCB, we help you make the right decision from the start — so you can build smarter, more reliable products, faster.

📩 Need Help Deciding?

Upload your design files or contact our engineers at HighPCB to get a free design consultation. Whether you’re unsure about the type of PCB or looking for a trusted manufacturing partner — we’re here to help.