A Unified Guide to FR-1, FR-2, FR-3 & High-Tg FR-4 Laminates (Epoxy PCB)

Epoxy PCB Family at a Glance

| Laminate | IPC Slash Sheet | Core Reinforcement | Resin System | Typical Tg | Punch-ability | Pb-Free Reflow | Relative Cost (to FR-4 = 1.0) |

| FR-1 | /21, /22 | Paper | Phenolic* | 125 – 135 °C | ★★★ | ✖ | 0.40 |

| FR-2 | /10, /11 | Paper | Phenolic* | 100 – 110 °C | ★★★ | ✖ | 0.35 |

| FR-3 | /12 | Paper | Epoxy | 120 – 135 °C | ★★☆ | Borderline (<245 °C) | 0.55 |

| FR-4 (High-Tg) | /126, /130 | Woven Glass | Epoxy (enhanced) | 170 – 200 °C | ☆ | ✔ (260 °C) | 1.00 |

* Although FR-1/FR-2 use phenolic resin, their production route and epoxy compatibility place them inside the “epoxy-class” supply chain.

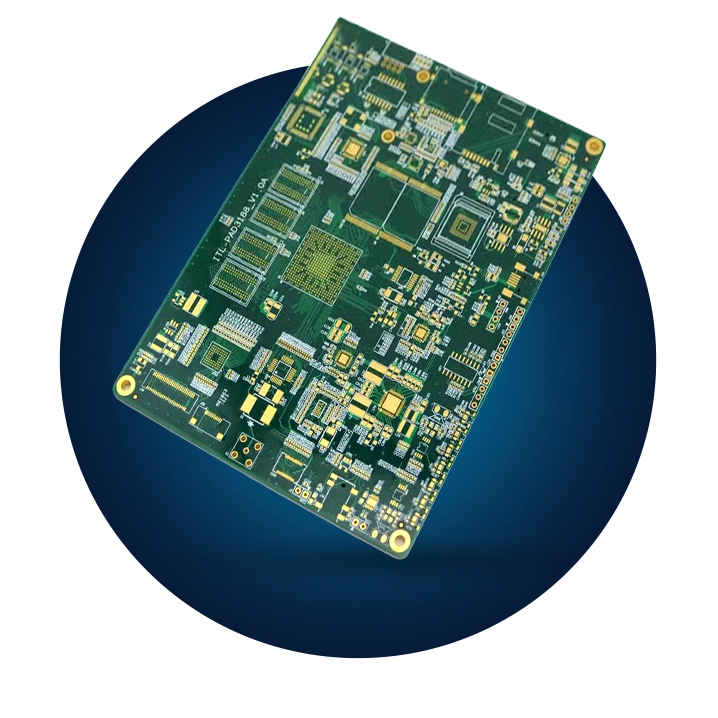

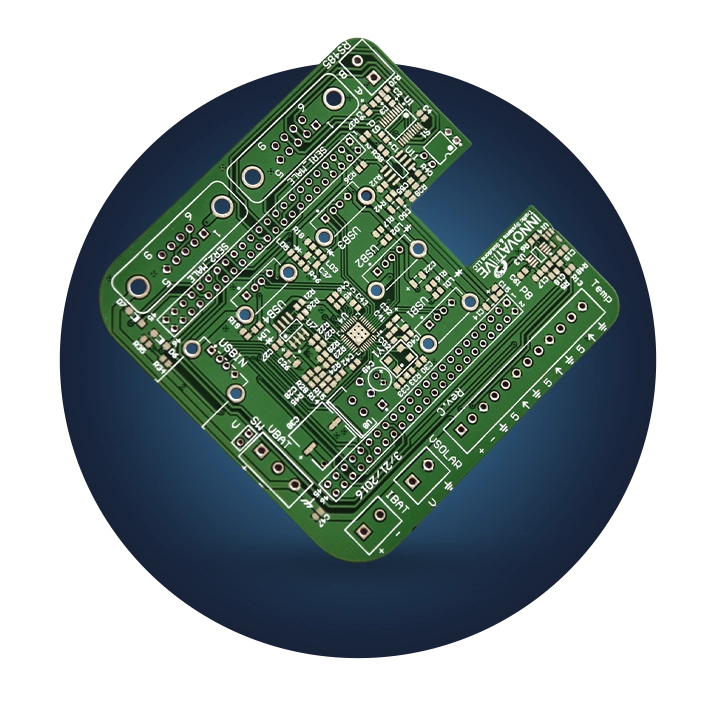

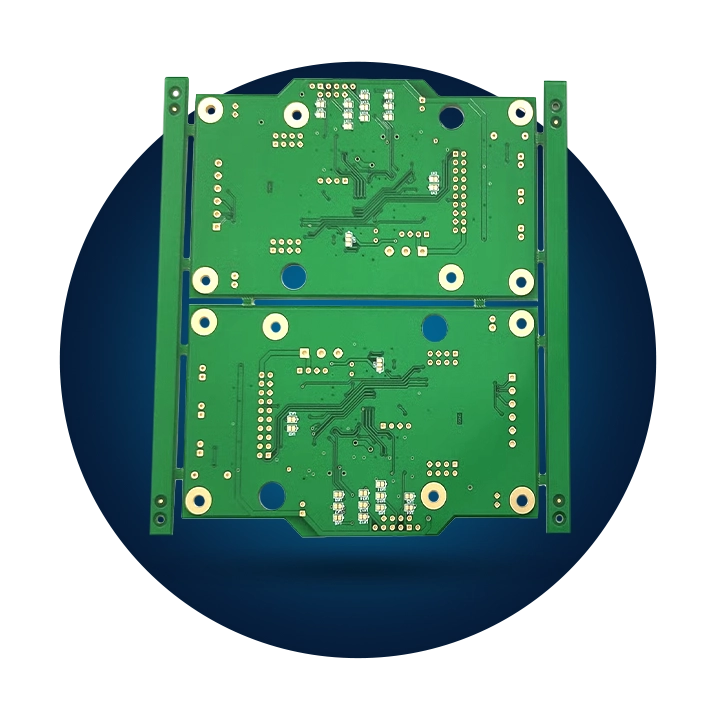

Epoxy PCB Fabrication

HIGHPCB is one of the largest Rigid PCB manufacturing factories in China, click on the link to see more.

Why Epoxy-Class Laminates?

Cost tiers for every budget

Scalable processing

Better solder-mask adhesion

RoHS & REACH-ready

Application Matrix

| Market Segment | FR-1 | FR-2 | FR-3 | High-Tg FR-4 |

| Battery toys / promotional gadgets | ● ● ● | ● ● ● | ● ● | – |

| Wall chargers ≤ 15 W | ● ● | ● ● ● | ● ● ● | – |

| Appliance controllers | – | ● ● ● | ● ● ● | ● ● ● |

| LED drivers (≤ 40 W) | – | ● | ● ● ● | ● ● ● |

| Industrial & automotive Pb-free | – | – | – | ● ● ● |

| High-speed (> 100 MHz) | – | – | ♦ (80 MHz max) | ● ● ● |

= Recommended ♦ = Feasible with care – = Not recommended

Design & Fabrication Essentials

| Parameter | FR-1 / FR-2 | FR-3 | High-Tg FR-4 |

| Min. trace / gap | 0.25 / 0.25 mm | 0.20 / 0.20 mm | 0.10 / 0.10 mm |

| Recommended copper | 35 µm (50 µm ≥ 2 A) | 35 – 70 µm | 35 – 105 µm |

| Board thickness | 1.2 / 1.6 mm | 1.0 – 1.6 mm | 1.0 – 3.2 mm, multilayer |

| Via plating | Not economical; use jumpers | Optional PTH | Blind / buried / filled µ-vias |

| Surface finish | OSP / Sn-Pb HASL | OSP / Sn / ENIG | ENIG, ENEPIG, ImAg, OSP |

| Max panel (punch) | 350 × 450 mm | 350 × 450 mm | 510 × 610 mm (routed) |

Grade-by-Grade Deep Dive

1. FR-1 – Ultra-Economy Paper-Phenolic

- Target price: ≈ 40 % of FR-4.

- Electrical: εr ≈ 5.1; suitable to ~30 MHz.

- Thermal: Tg 130 °C → Sn-Pb wave only.

- Ideal for: Greeting-card sound boards, LED nightlights, disposable med-strips.

- Tip: Keep continuous tracks ≤ 1 A per 2 mm; add Al slug under TO-220 parts.

2. FR-2 – Low-Cost with Slightly Lower Tg

- Tg 105 °C, cost ~5 % lower than FR-1.

- Punchability identical to FR-1; CTI ≈ 125 V.

- Great for: Budget AM/FM radios, IR remotes, 15 W chargers.

- Caution: No Pb-free reflow; avoid heavy transformers.

3. FR-3 – Paper-Epoxy Bridge Grade

- Epoxy resin improves bond strength & mask adhesion.

- Tg 120 – 135 °C, still punch-friendly.

- Selective Pb-free (≤ 245 °C) possible for light SMT.

- Use-cases: 40 W LED drivers, smart plugs, appliance keypads.

- Design rule: 0.20 / 0.20 mm trace/space; optional PTH if cost allows.

4. High-Tg FR-4 – Glass-Epoxy for Reflow & Multilayer

- Tg 170 – 200 °C, Z-CTE 45–55 ppm /°C → robust at 260 °C reflow.

- Electrical: εr 4.2@1 GHz, tan δ 0.015.

- Supports: 1–16+ layers, µ-vias, controlled impedance to 28 Gb/s.

- Industries: Automotive ADAS, servers, telecom, high-power lighting.

- Pro-tip: Simulate thermal expansion stack-up to avoid CAF in >8-layer boards.

Quick Selection Cheat-Sheet

| If you need… | Choose … | Because |

| Lowest possible BOM for a throw-away gadget | FR-1 | Cheapest laminate; punch in one hit |

| Ultra-low price plus slightly more thermal margin | FR-2 | Tg ≈ 105 °C; identical processing |

| Punchability + better solder-mask adhesion | FR-3 | Epoxy resin; survives selective Pb-free |

| Lead-free reflow, multilayer, high-speed | High-Tg FR-4 | Glass-epoxy, Tg ≥ 170 °C, µ-vias |

Support All Types of PCB Fabrication

Why Partner with HighPCB for Epoxy Boards?

- Laminate breadth – FR-1, FR-2, FR-3, CEM-3, standard & high-Tg FR-4 in stock.

- Dual tooling lines – steel-rule punch for paper cores; laser/CNC for glass-epoxy multilayers.

- 48-h DFM and impedance modelling for every order.

- Rapid lead-times: 3-day FR-3 prototypes, 7-day FR-4 multilayers.

- One-stop service: stencil, assembly, conformal coat, ICT & functional test.

Need to balance cost, thermal performance and reliability?

Request an instant epoxy PCB quote from HighPCB today—our engineers will match the perfect laminate to your design goals.

FAQ

1. Are all epoxy PCBs RoHS compliant?

Yes. HighPCB sources only RoHS 2 & REACH-ready epoxy laminates; halogen-free FR-4 is available if UL 94 V-0 is required.

2. Can FR-3 be used for SMT with Pb-free solder?

Selective or low-temperature BiSnAg reflow (< 245 °C) is feasible; avoid full JEDEC profiles.

3. How large a board can be punched?

FR-1/2/3 up to 350 × 450 mm; FR-4 panels 510 × 610 mm (routed).

4. What copper thickness should I specify for 2 A continuous on FR-2?

50 µm copper with ≥ 2 mm trace width or add external copper jumpers.