In the medical sector, HIGHPCB focuses on design, manufacturing, and assembly; CT scanner PCB, endoscope imaging system, hematology analyzer PCB, ventilator PCB, etc.

The current trend of many wearable and therapeutic devices, such as devices that monitor vital signs, fitness, or clinical monitoring, promotes devices with non-standard PCB shape parameters, such as round or elliptical. Also, PCBs can have quite irregular shapes. The integration of flexible and rigid-flexible (very compact and high component density) PCBs allows designers to easily manage different types of printed circuit boards.

Specialized Medical Boards: Design and Manufacturing Capabilities

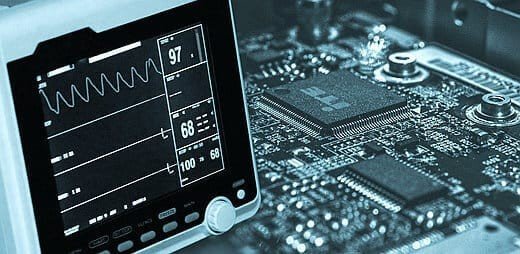

Medical devices are becoming increasingly complex, with more and more functionality being integrated into smaller and smaller packages. This has led to the development of specialized medical boards, which are designed to meet the unique needs of the medical industry. In this article, we will discuss the different types of specialized medical boards and the manufacturing capabilities of our company.

Types of Specialized Medical Boards

There are several types of specialized medical boards, each designed for a specific application. Some of the most common types include:

- Patient Monitoring Boards: These boards are used to monitor vital signs such as heart rate, blood pressure, and oxygen saturation. They are typically small and portable, and are designed to be used in a variety of clinical settings.

- Imaging Boards: These boards are used in medical imaging applications such as X-ray, MRI, and CT scans. They are designed to provide high-quality images with minimal noise and distortion.

- Surgical Boards: These boards are used in surgical applications such as endoscopy and laparoscopy. They are designed to be compact and easy to use, while providing high-quality video and audio feedback.

Manufacturing Capabilities

Our company has extensive experience in the design and manufacture of specialized medical boards. We have a team of experienced designers who can work closely with customers to develop customized solutions that meet their specific requirements. Some of the key manufacturing capabilities of our company include:

- Advanced Materials: We use advanced materials such as high-density interconnect (HDI) boards, flexible circuits, and rigid-flex circuits to create specialized medical boards that are durable, reliable, and compact.

- Miniaturization: Our team of designers is skilled in the art of miniaturization, and can create specialized medical boards that are small enough to fit into the most compact medical devices.

- Testing and Quality Control: We use the latest testing equipment and techniques to ensure that our specialized medical boards meet the highest standards of quality and reliability. All of our boards undergo rigorous testing before they are shipped to customers.

Conclusion

Specialized medical boards are an essential component of modern medical devices. They are designed to meet the unique needs of the medical industry, and are becoming increasingly complex and sophisticated. At our company, we have extensive experience in the design and manufacture of specialized medical boards. Our team of skilled designers and technicians can work closely with customers to develop customized solutions that meet their specific requirements. If you are looking for a reliable partner for your specialized medical board needs, please contact us to learn more about our capabilities.